| | 02/05/2014 |  I spent most of the past week helping my parents pack and trying to sort out my stuff that has been at their house. It brings back memories. And that's what my mind has been on all week. I spent most of the past week helping my parents pack and trying to sort out my stuff that has been at their house. It brings back memories. And that's what my mind has been on all week.

My first job out of college was working at the Industrial Construction division at Black & Decker in Hampstead, Md. They put me to work designing power tools - something that it became readily apparent I wasn't very good at but I learned a tremendous amount in the year and a half I worked there. I learned from my colleagues, I learned by watching. I still quote from my experiences there to the folks here at TFWW. It was an amazing time for me.

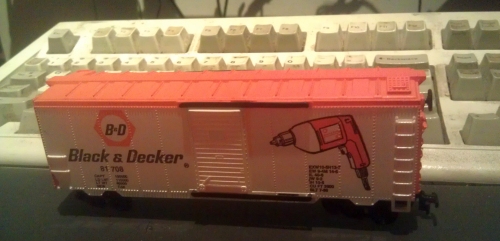

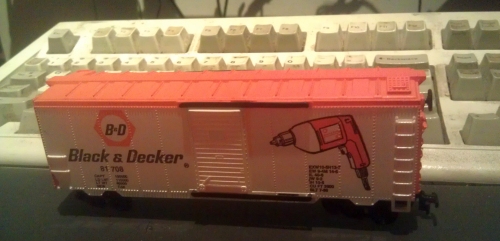

Every lunchtime we used to walk most of the length factory to the company cafeteria and back, passing the company store. We used to pop by the store at least once or twice a week where we could buy various seconds of tools, the odd souvenir and things like this very limited edition train car in the picture. In my time there I assembled fairly good collection of C. 1980 power tools from the company store and at the time they were the best tools you could get - I will probably write about them in the future. But while I have great nostalgia for my time there, power tool technology has gotten a lot better over the years. And while I feel that, especially when it comes to traditional tools, the older designs if well done can't be beat, seeing how modern technology can push the design of a fret saw or a coping saw is really interesting and keeps me from constantly looking backwards.

This is a really exciting time to be an iron monger. In the past 10 or 15 years we have seen a revolution in the design and availability of well made and well working hand and power tools. The hand tools in both traditional and new designs work better than ever, and power tools are easier to use, more functional and safer than ever before. This is happening just as the need for these tools is peaking. The end product, furniture, has been left behind. Furniture itself as a possession is less important than it was. For all the advances in tools building a Newport highboy, or a Ruhlman bureau is still really hard to do and takes skill and practice more than just fancy tools. Skill is skill and that won't change, but I hope we are on the verge of something new, and in a few weeks I hope to be reporting on what I think is the most interesting development in hobbyist furniture design in decades.

| Join the conversation | |

| The opinions expressed in this blog are those of the blog's author and guests and in no way reflect the views of Tools for Working Wood. |

|

Joel's Blog

Joel's Blog Built-It Blog

Built-It Blog Video Roundup

Video Roundup Classes & Events

Classes & Events Work Magazine

Work Magazine

I spent most of the past week helping my parents pack and trying to sort out my stuff that has been at their house. It brings back memories. And that's what my mind has been on all week.

I spent most of the past week helping my parents pack and trying to sort out my stuff that has been at their house. It brings back memories. And that's what my mind has been on all week.

Also, are you ever going to get the 1/2 inch mortise chisel in stock? I've been waiting for months on that one. Seems that forever out of stock is a very common thing on your site.

I worked in the Industrial Construction division - no plastic, aluminum housings, real bearings, expensive tools. We made the best power tools made in the USA at that time with real innovation. Our competitors were other industrial tool makers like Milwaukee, Metabo, and Festo. During that time the B&D consumer division was making three grades of not so great tools which were what you would buy in Sears and normal stores. This was before Makita and Hitachi has any real impact in the market. 10 years later all of this was gone. None of the professional grade tool companies in the US are left - they are brands only.

I bought a 110v B&D to replace it - first outing on a 16mm (5/8") hole in a steel joist it stripped a tooth off the main pinion (my old Wolf would have done it with no problem).. I could have got a new gear, but it was over half the price of the drill...

Instead I invested in a JCB brand (a well known company in the UK, making tractors and back-hoe diggers etc) - I figured if JCB had backed the company it would be good quality. Mechanically very sound, and immensely powerful at 1010 watts, the Chinese made winding lasted 20 minutes before they burnt out. It's replacement lasted a little longer at a week, and that one's replacement about a month..

The Wolf name is still used, but the company is based in India - I guess of a similar quailty to the JCB... Finally I bought a DeWalt (same company as B&D) - that appears to be well built...

If I want to drill a really big hole, I still have a 1950's aluminium bodied two handed Wolf with a 5/8" chuck that will break your arm if the drill bit catches....

Here in the UK, we have stopped manufacturing almost all power tools, everything is made in China, Taiwan or India - profit now comes before quality. However some Chinese made tools are good, and often made in the same factory as the junk - it must just be a question of quality control....

Or we import it from the US or Germany.... Can anyone tell me why in the US Dewalt offer a three year warranty on batteries, in the UK it is only a year - and the price here in GB£ is the same figure as in USD - i.e. about 1.7 times more expensive...